While climbing down a 400-foot telecommunications tower, a worker lost his footing and fell to his death. His fate would have been different had the ladder safety system of the carabiner, carrier rail, safety sleeve, and body harness prevented his fall. But, the safety sleeve did not activate properly, and the worker plunged 90 feet to death. Tragic, isn’t it? Preventable? Yes.

Sadly, every year the Bureau of Labor Statistics reports thousands of deaths (1,008 in 2020) and more than a hundred-thousand injury and illness cases (174,100 in 2020) in the construction industry - the chart-topper. Falls remain the leading cause of work-related deaths in construction, accounting for more than one in three (36.4%) of the total number of fatalities in this industry. Top safety violations of 2021 that are most common in the construction industry are- (no.1) fall protection, (no.3) ladders, (no.5) scaffolding, (no.6) fall protection training, and (no.8) eye and face protection.

With heavy-duty machinery, moving parts, power tools, and countless other hazards - it’s perhaps not surprising that life is always at stake and serious accidents are lurking from every corner at a construction site.

As much as the safety of a worker is concerned for obvious humanitarian reasons, employers have a lot to lose too when a fatality or injury happens. If safety is prioritized, most incidents, deadly or not, can be prevented.

What are the common causes of construction accidents?

According to the Occupational Safety and Health Administration (OSHA), these are the 4 most common causes (also called OSHA’s “Fatal Four”) of fatalities in the construction industry:

- 1. Falls (usually from heights)

- 2. Electrocutions

- 3. Struck by an object

- 4. Caught in (or in between) machinery

What losses do construction employers face due to workplace accidents?

Accidents are expensive. Read through some of these important points to understand why construction safety is vital in more ways than one.

Productivity Loss

Research published in the renowned medical journal BMJ reveals that an American employer loses 11 days of work every year due to non-fatal injuries suffered by an employee. Work delays due to the absence of expert employees are difficult to replace.

Business Loss

Losing an experienced worker who may not be easily replaceable will cost time and money. Apart from not being able to complete a construction project on time due to impaired workers who may take weeks or months to recover, companies need to pay hefty insurance premiums which ultimately is a burden on profits.

Medical Costs

Cases in which it is proved that the injury or accident is a result of an employer’s negligence, bring a lot of financial burdens. Workers' compensation includes lost wages, medical treatment, ongoing care costs, and sometimes, disability leave costs.

Penalties

Employers are required to report any workplace accident that results in a fatality within eight hours and incidents that result in hospitalizations or amputations within 24 hours. After the accident, the safety authorities inspect the workplace to identify and correct root causes. On finding any fault, the construction company may be fined and the person in charge may even face jail time for jeopardizing the safety of employees. In 2018, a total of 25,294 citations resulted from 10,291 inspections in the construction industry. The total penalties resulted in $73,660,506 averaging around $2,900 per penalty.

Reputation

Businesses also suffer from low staff morale and loss of reputation. Not being able to deliver a project timely due to injuries and accidents on site, sure takes away from a construction company’s reputation. The industry may label such firms as “unsafe companies”, that no one wants to work with.

Employee Morale

Due to unsafe conditions prevailing in the workplace, construction employees may develop a lack of trust, discontentment, and fear - that all ultimately affect the overall health and productivity of the worker.

How can employers ensure construction safety?

Employers in the construction industry can safeguard their employees against common injuries, illnesses, and fatalities by using the following tools and approaches:

PPE

Personal Protective Equipment is an essential measure. Each PPE, like hard hats, safety goggles, flame-retardant bodysuits, hi-visibility vests, rubber gloves, steel toe shoes, etc., has different ratings by the manufacturer, suitable for different working requirements. The employer chooses the appropriate PPE for the safety of employees that will likely save their lives in an accident.

Elimination/Substitution/Reduction of Hazards

Though not always possible, eliminating hazards is the most effective means of safety in the construction industry. For example, employers can upgrade aging, unsafe machinery with a new one equipped with more safety features. Adding machine guards are a great way to reduce hazards.

Engineering Controls

More than often, employers can't eliminate or substitute a hazard. To handle such situations, engineering controls, in which the employer makes physical changes at the job site, come into play. For example, changing the sequencing of a demolition plan to avoid struck-by hazards or mounting a fence around a hazardous location to restrict entry.

Administrative Controls

These controls include establishing rules, operating procedures, and displaying construction signs, alarms, or sirens. For example, in the case of heavy equipment operators, one could develop a foolproof communication plan to ensure safety around moving machinery, implement a lockout / tagout program, or adopt policies regarding the use of warning signs.

How can signs reduce the chances of accidents at a construction site?

Standard 1926.200 of OSHA outlines the type of signs that should be installed at construction sites to maintain and improve safety. Visual communication tools like signs, tags, barricades, floor tapes, etc., are essential for improving the safety of a construction environment, operating efficiently, and keeping employees informed of dangers around them.

Useful signs and tags for a construction area include -

The most important one of the lot includes all danger, caution, notice, and safety header signs, meant to warn workers.

These large scoreboards clearly display your employee’s accident-free work days and instill confidence in your workforce.

Floor tapes are a perfect solution for any indoor construction site where workers need to be guided of specific rules, and hazardous areas can be demarcated clearly.

Many devices like conveyor belts, electrical panels and milling machines need LOTO procedures to prevent hazards and control electrical energy at construction sites.

Banners are printed on durable, reinforced vinyl with metal grommets for hanging. Gets attention without fail. Posters can be ordered on adhesive-based SmartTex, lightweight corrugated, or heavy-duty HDPE.

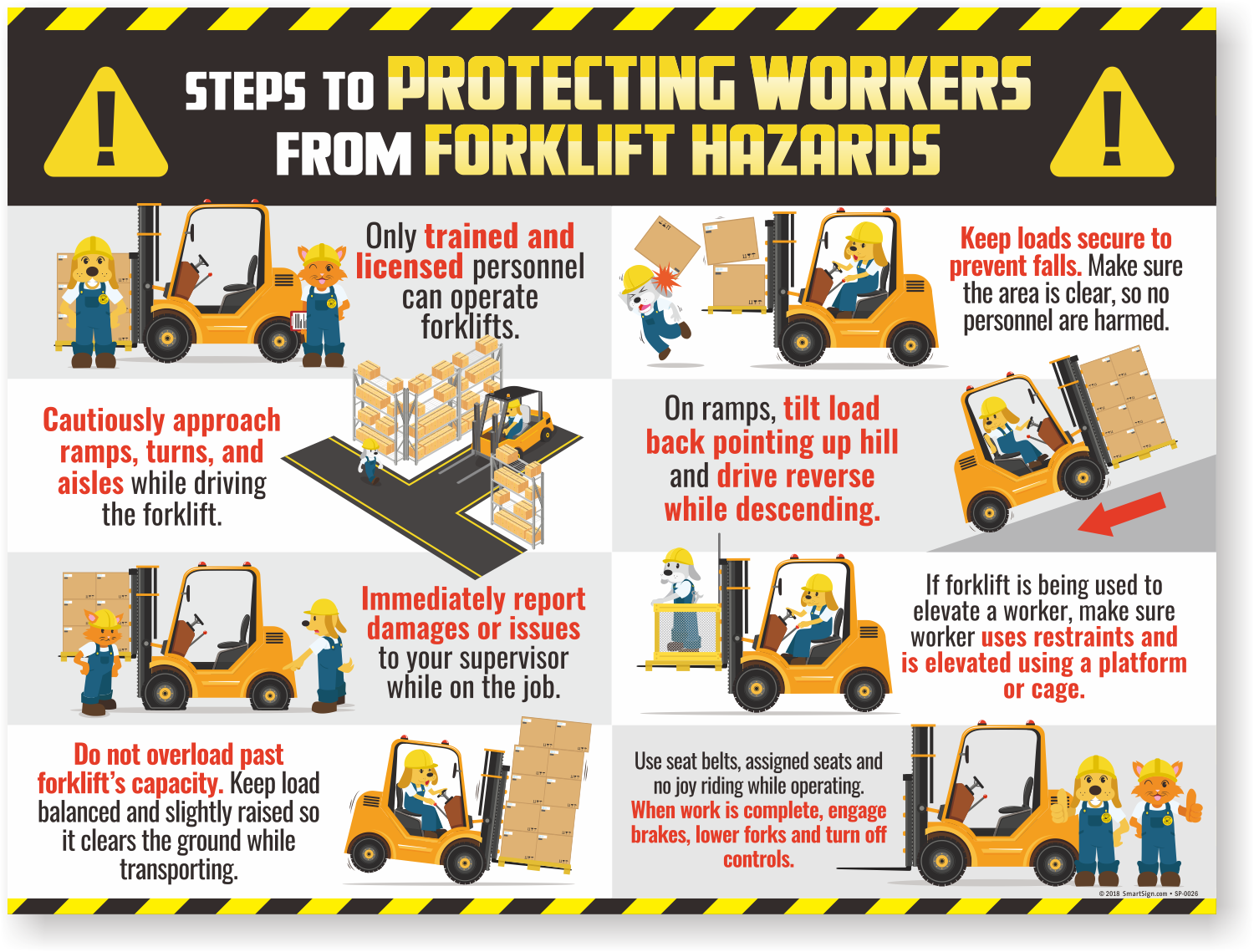

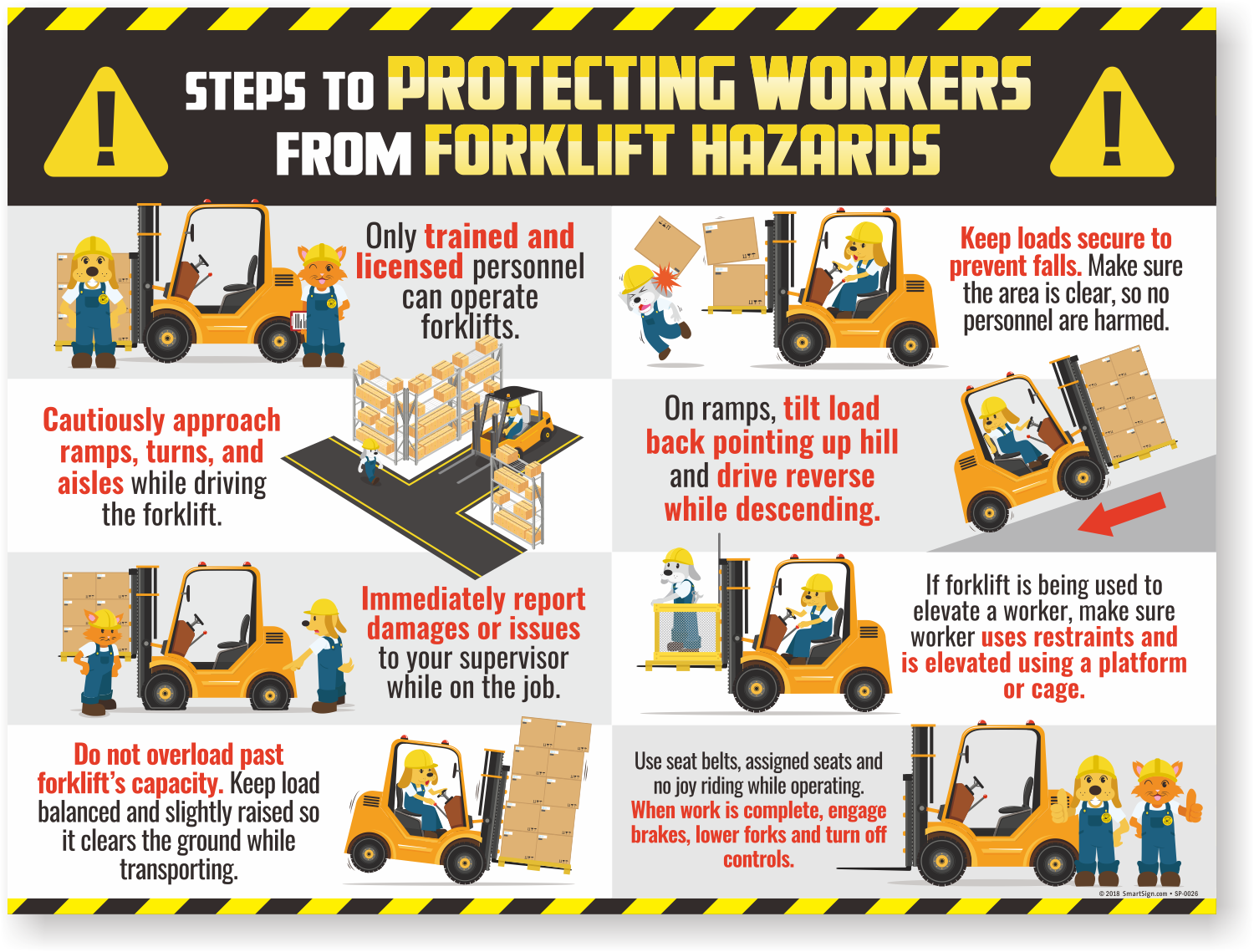

These labels with a free QR code can take your workers to training modules, machine manuals, and general safety information. They can be directly placed on cranes, forklifts, and other machines.

Spatial awareness is critical at a construction site to avoid hazardous areas.

These are portable and a physical means of restricting entry or drawing attention to a particular hazard at the job site.

A safety cone is one thing that is easily available at a construction site. The portable cone can be easily turned into a communication tool with a cone-top sign. The sign bearing a message for construction workers has a holder that quickly locks onto the top of any cone.

Who is liable for death and injuries in construction?

Apart from the workers' compensation system, third parties like contractors, subcontractors, designers, engineers, equipment suppliers, landowners, and manufacturers may all have varying levels of civil and product liability. This depends on their involvement in the product supply and their control over the property itself. Individual cases must be studied case-to-case basis to determine who was liable and to what extent. Whether the victim can bring a personal injury lawsuit for damages, such as pain and suffering, against other responsible parties varies from state to state. Liability can be due to defective equipment, lack of appropriate safety gear, inadequate training, and improper safety protocols.

In some states, once a plaintiff establishes a violation of OSHA regulations and the violation caused an injury, the injured person will not have to establish anything further to prove that the party that violated the regulation was negligent. Violating any safety rules put forward by the property owner or general contractor may also be a basis for liability.

In a 1992 Toland v. Sunland Housing Group, Inc. case, Timothy Toland, employed under the contractor CLP Construction, Inc. (CLP) at a housing development, got injured when a wall fell on him. The victim and CLP sued the project's owner Sunland Housing Group, Inc. (Sunland), under the Workers' Compensation Act. Toland alleged that raising the wall created a peculiar risk of injury for which Sunland should have required subcontractor CLP to take special precautions.

In a 2005 Kinsman v. Unocal Corp. case, the Supreme Court ruled that a landowner can be liable to an independent contractor when the contractor is injured by concealed hazards. Landowner was at fault since the contractor did not know about the hazard and reasonably could not have discovered it on their own.