Minimum Clearance Around Electrical Panels (Carrying 600 Volts or Less)

Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety. Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an accident.

Blocking electrical panels is a violation of regulations set by the federal Occupational Safety and Health Administration (OSHA) and the National Electrical Code (NEC) published by the National Fire Protection Association (NFPA).

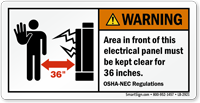

NEC 110.26 and 29 CFR 1910.303(g)(1) require sufficient access and working space around electric equipment to allow ready and safe operation and maintenance of such an equipment. Both the OSHA and NEC set minimums for the dimensions of this working space. Let’s look at them in some detail.

Depth of working space around electrical equipment NEC 110.26(A)(1)

OSHA and NEC guidelines require clear working space around electric equipment as follows:

| Nominal voltage to ground | Minimum clear distance for condition 23 | ||

| Condition A | Condition B | Condition C | |

| ft. | ft. | ft. | |

| 0-150 | 13 | 13 | 3 |

| 151-600 | 13 | 3.5 | 4 |

Minimum clear distances may be 0.7 m (2.5 ft.) for installations built before April 16, 1981.

2. Conditions A, B, and C are as follows:

Condition A — Exposed live parts on one side and no live or grounded parts on the other side of the working space, or exposed live parts on both sides effectively guarded by suitable wood or other insulating material. Insulated wire or insulated busbars operating at not over 300 volts are not considered live parts.

Condition B — Exposed live parts on one side and grounded parts on the other side.

Condition C — Exposed live parts on both sides of the workspace (not guarded as provided in Condition A) with the operator between.

3. Working space is not required in back of assemblies such as dead-front switchboards or motor control centers where there are no renewable or adjustable parts (such as fuses or switches) on the back, and where all connections are accessible from locations other than the back. Where rear access is required to work on de-energized parts on the back of enclosed equipment, a minimum working space of 762 mm (30 in.) horizontally shall be provided.

Width of working space around electrical equipment NEC 110.26(A)(2)

Working space around electrical equipment must be as wide as the equipment or 30 inches, whichever is greater.

Height of working space around electrical equipment NEC 110.26(A)(3)

For installations built before August 13, 2007, the height of the working space must be 6.25 ft.

For installations built on or after August 13, 2007, the height must be at least 6.5 ft. from the floor, grade, or platform. It can’t be lower than the height of the equipment.

In every case, the width, depth, and height of the working space around electrical equipment must allow all equipment doors or hinged panels to open at least 90-degrees.

Updates to working space clearance around electrical equipment (according to NEC 2017)

When an energized equipment requires servicing/repair but it is situated in a space with limited access:

The opening to electrical equipment installed above a suspended or a lay-in ceiling must be at least 22 in. x 22 in.

The opening to an electrical equipment installed in a crawl space must be at least 22 in. x 30 in.

Category: Resources