Crane Inspection Checklist

Before conducting a successful crane safety inspection, it’s important to understand the kind of inspection you need to perform. Crane inspections are of two types—frequent and periodic [20 CFR 1910.179(j).]

[Note that OSHA Standard 1910 covers only general industry. For cranes used in construction and shipyards, see 29 CFR parts 1926 and 1915, respectively.]

- Frequent inspection—Daily to monthly interval

- Periodic inspection—1 to 12-month interval

We’ve covered both inspection procedures for overhead and gantry cranes only in our post. Make sure you check with your safety professional if you have any doubts.

Frequent Inspection Checklist

1. On a daily basis, look for all maladjustments that are interfering with proper operation of the crane.

2. Daily inspect any deterioration or leakage in lines, tanks, valves, drain pumps, and other air or hydraulic systems.

3. Check for damage like any deformed or cracked hook. This should be done daily as well as monthly. For monthly inspections, maintain a certification record with the inspector’s signature and date.

4. Hoist chains including the end connections should be checked for deformities. Again, the wear, twist or distortion inspection should be a daily and monthly exercise in the same manner as hooks.

OSHA standard 1910.179(j)(2)(iv) states that hoist chains should be inspected with a certification record that includes date of inspection, signature of the person who performed the inspection and an identifier of the chain which was inspected.

5. Look for excessive wear of components as need be.

6. Check whether the wire rope reeving system is working according to manufacturer’s recommendations.

Periodic Inspection Checklist

These are additional inspection steps to be performed along with frequent inspections, but on an annual basis:

1. Inspect deformed, cracked or corroded members.

2. Look for loose bolts or rivets; cracked or worn sheaves and drums; worn, cracked or distorted pins, shafts, gears, bearings, rollers, locking and clamping devices.

3. Now see if there is excessive wear on brake and clutch system parts, linings, pawls, and ratchets.

4. Check for any inaccuracy in load, wind, and other indicators.

5. Make sure to check faulty or unsafe powerplants (such as leaking exhaust and emergency shut-down feature.)

6. Inspect excessive wear of chain drive sprockets and extreme chain stretch.

7. Electrical apparatus should be checked to see pitting or any other deterioration of controller contactors, limit switches and pushbutton stations.

8. Tires for damage or excessive wear.

Inspectors must also inspect cranes that are not used on a regular basis and standby cranes.

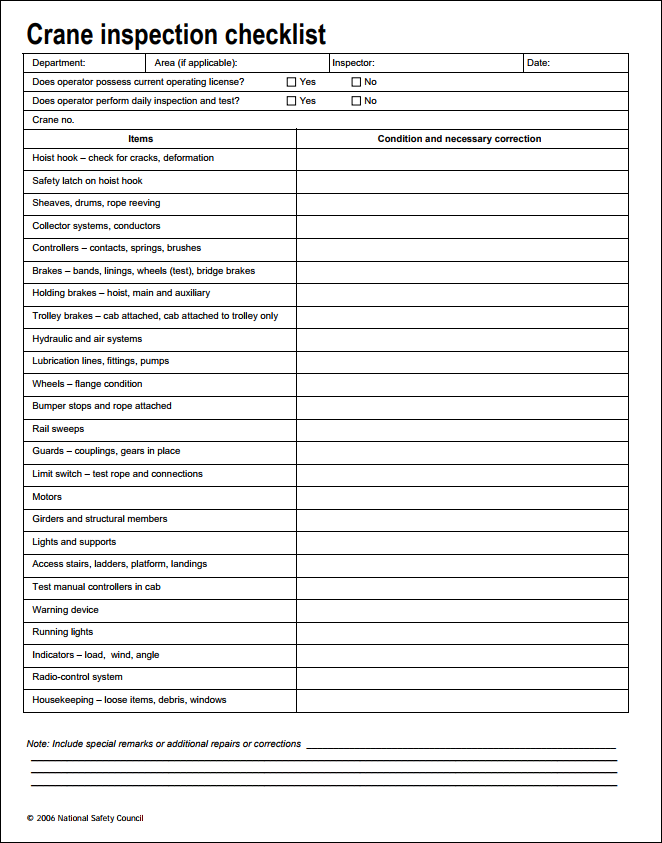

Here’s a complete Crane Inspection Checklist released by National Safety Council in 2006 —

Category: Resources