Safety Checklist: Forklift Battery Charging Areas

Charging forklift batteries requires training and caution due to the batteries’ weight, the corrosive sulfuric acid contained within, the possibility of explosive hydrogen fumes, and the chance of electric shocks on unprotected exposure.

The Occupational Safety and Health Administration (OSHA) standard, 29 CFR 1910.178(g), lays out the safety requirements for forklift battery charging areas.

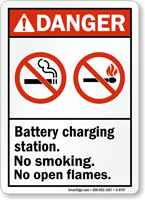

Hydrogen gas is always present during battery charging, and hydrogen gas is explosive. As such, you should take precautions to prohibit open flames, sparks, or electric arcs in the battery charging areas, and provide good ventilation so that the hydrogen gas doesn’t concentrate.

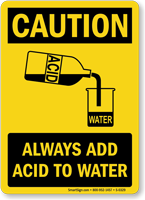

Spills are another potential hazard. To prepare for spills, have ample and readily accessible water, and use neutralizing agents like baking soda or soda ash to neutralize spilled sulfuric acid. For larger spills, workers must contact the fire department to control the spill accurately and prevent any environmental damage in the process.

A dry chemical, CO2 or foam fire extinguisher must be at hand too. Mark safety equipment like fire extinguishers with proper signage to ensure workers can spot them quickly.

This minimizes dangers to workers and the battery itself. When handling batteries using cane, workers should also wear hard hats to protect themselves against impact hazards.

A safety warning sign like this can keep this point fresh in a worker’s mind during battery charging operations.

Post a clear and conspicuous warning sign like this one to prevent smoking and open flames. A sign with appropriate graphics gets the message across more swiftly.

Place this sign near battery chargers to alert workers of this rule. You can also create a custom sign specific to other metallic objects your workers may have on them.

Other important safety measures to have in place

For larger installations, OSHA requires a plumbed drench shower along with an eyewash station.

Check OSHA’s recommended practices for safe forklift charging procedure and battery maintenance for more details.

Category: Resources