How to inspect scaffolding safety

Scaffolds can collapse due to instability or overloading. Always inspect scaffoldings to make sure hazards do not result in tragedies.

When Should You Inspect Scaffolding?

As per OSHA regulations, 29 CFR 1926.451, scaffolding should be inspected:

- after installation / before first use

- at least every week

- every time after adverse weather conditions like high wind which can affect a scaffold’s structural integrity

Who Should Inspect the Scaffolding?

Scaffolding should be inspected by a competent person whose combination of knowledge, training and experience is appropriate for the type and complexity of the scaffold and who has the authorization to take prompt corrective measures to eliminate identified hazards around scaffolds.

How to Inspect Scaffolding Safety?

Employers should strive to protect their employees from common scaffold-related hazards such as falls, falling objects, structural instability, electrocution, and overloading. Here’s is a checklist for periodic inspection of a scaffold. Inspection should be carried out for all the following components of a scaffold:

Scaffold Base and Structure

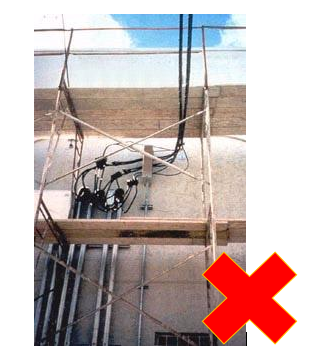

1. De-energize power lines near scaffolds and ensure there are no power lines, tools or materials within 10 feet of scaffoldings.

Keep scaffold away from electrical lines

2. Check if the type of scaffold is right for the loads, materials, workers and weather conditions.

3. Inspect footings to see if they are level, sound, firm, and can support the loaded scaffold.

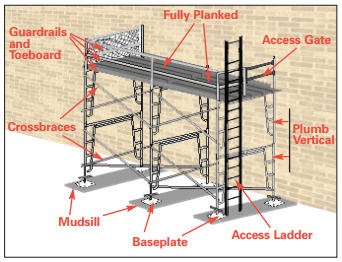

4. Ensure that the legs, posts, frames and uprights are on baseplates and mudsills.

5. Ensure there are no bends, holes, cracks, rust, pits, welding splatter, broken or, and non-compatible parts in the metal components or scaffold.

6. Check for safe access. The crossbraces should not be used as ladder for access or exit.

7. A competent person must inspect ropes (in case of suspended scaffolds) for defects prior to each work shift and after every occurrence that could affect the rope’s integrity.

Here’s an illustration showing different parts of a scaffolding that need to be inspected [Source: Planks

1. Inspect wooden planks and ensure there are no cracks or splits greater than 1 /4-inch, long end splits, several large loose knots, warps greater than 1 /4 inch, boards and ends with gouges, mold, separated laminate(s), and grain sloping greater than 1 in 12 inches from the long edge. Planks must be scaffold grade lumber or equivalent.

[caption id="attachment_6734" align="alignleft" width="140"] Plank has a long split and unable to bear load

Plank has a long split and unable to bear load

Plank with notches (small checks on the end)

Plank with checks (cracks that are only on the surface)

2. Planks that deflect 1 /60 of the span or 2 inches in a 10-feet wooden plank, are damaged and should not be used.

3. Ensure planks are close together, with spaces no greater than 1 inch around uprights.

4. 10-foot or shorter planks must be 6 to 12 inches over the centerline of the support. Longer planks should not be more than 18 inches over the end.

Platform

- Ensure that the platform is 14 inches or less from the wall or 18 inches or less away if plastering/stuccoing.

- Make sure there are guardrails and midrails on platforms where work is being done

- Check for workers under the platform and supplement protection from falling objects or barricade the area.

- Ensure that workers wear hard hats and fall protection.

5. Make sure braces, tie-ins and guying is used at each end, vertically and horizontally, and is done according to the scaffold manufacturer’s instructions. This will prevent tipping.

Scaffold Tagging and Inspection

All scaffolds shall be inspected and marked with proper identification tags by a competent person. Untagged scaffold should not be used. Scaffold tag should be fastened to the access ladder or near the stairway at the eye level so it is easy to locate.

Green Tags: Identify scaffolds that are safe for use.

Yellow Tags: Identify scaffolds which have been modified to meet work requirements, and as a result could present a hazard to the users.

- Yellow “Caution” tag indicates special requirements for safe use. It allows the erecting crew to identify which portion of the scaffold is incomplete.

- Potential hazard and preventative measures are marked on the back of the tag. The information also contains the name of the client company representative authorizing the use of scaffold.

- Yellow tag should not to be removed until the scaffold is safe to use and inspected by a “competent person.”

- Based on the results of that inspection, yellow tag should be replaced by appropriate tag (red or green).

Red Tags: Identify scaffolds that are unsafe for use.

- Red tags should have the work order number or project number, inspection date and name of the inspector on the front side.

Category: Resources, Uncategorized